Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

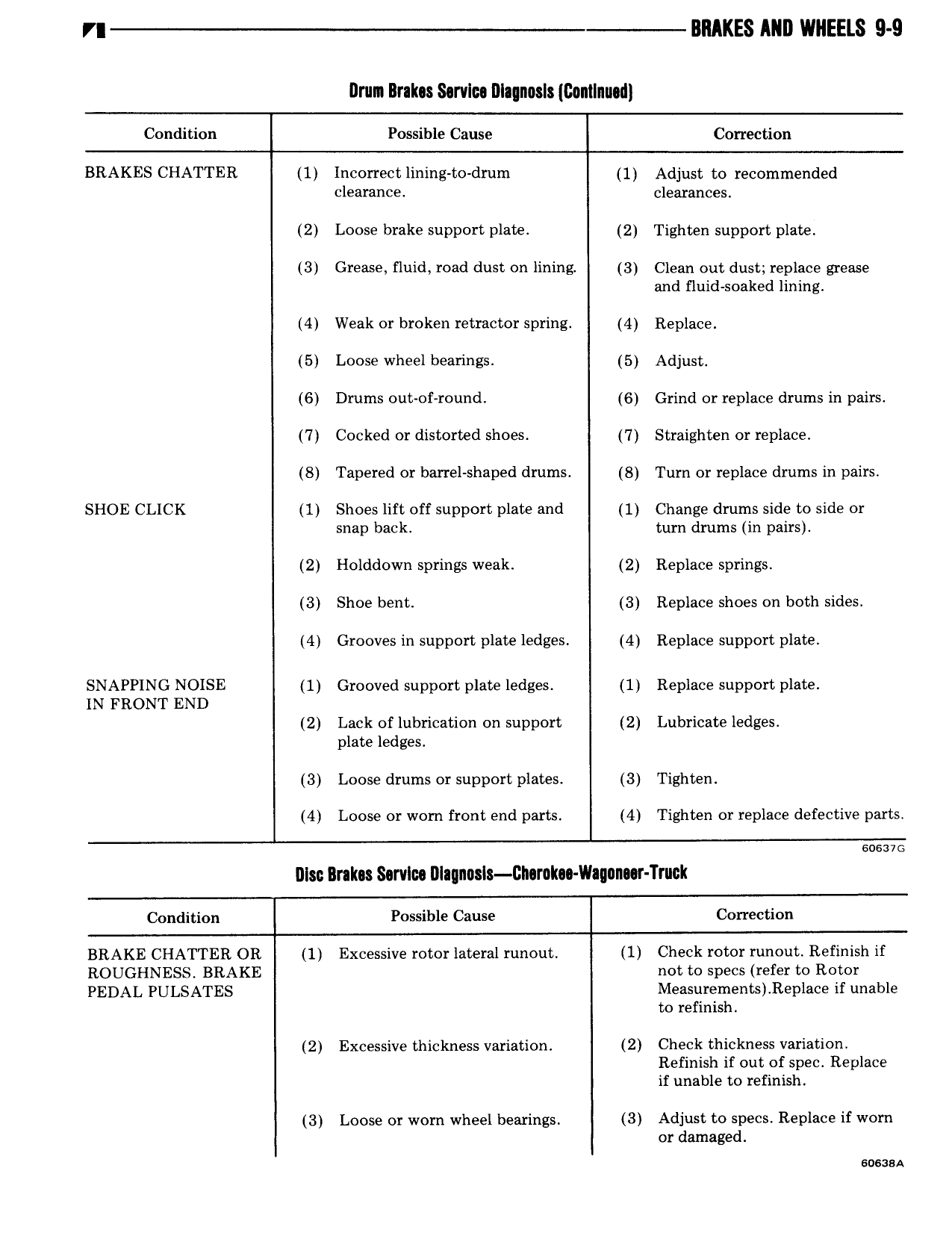

VI BRAKES MIB WHEELS 9 9 Ilnm Brakes Sarvlco Dlagnusls Conllnmdl Condition Possible Cause Correction BRAKES CHATTER 1 Incorrect lining to drum 1 Adjust to recommended clearance clearances 2 Loose brake support plate 2 Tighten support plate 3 Grease fluid road dust on lining 3 Clean out dust replace grease and fluid soaked lining 4 Weak or broken retractor spring 4 Replace 5 Loose wheel bearings 5 Adjust 6 Drums out of round 6 Grind or replace drums in pairs 7 Cocked or distorted shoes 7 Straighten or replace 8 Tapered or barrel shaped drums 8 Turn or replace drums in pairs SHOE CLICK I Shoes lift off support plate and 1 Change drums side to side or snap back turn drums in pairs 2 Holddown springs weak 2 Replace springs 3 Shoe bent 3 Replace shoes on both sides 4 Grooves in support plate ledges 4 Replace support plate SNAPPIN G NOISE 1 Grooved support plate ledges 1 Replace support plate IN FRONT END 2 Lack of lubrication on support 2 Lubricate ledges plate ledges 3 Loose drums or support plates 3 Tighten 4 Loose or worn front end parts 4 Tighten or replace defective parts Illsc Brakes Sarvlca DIagnosls Cnaroku Wagnn r Truck Condition Possible Cause Correction BRAKE CHATTER OR 1 Excessive rotor lateral runout 1 Check rotor runout Refinish if ROUGHNESS BRAKE not to specs refer to Rotor PEDAL PULSATES Measurements Replace if unable to refinish 2 Excessive thickness variation 2 Check thickness variation Refinish if out of spec Replace if unable to refinish 3 Loose or worn wheel bearings 3 Adjust to specs Replace if wom or damaged scsasa

Next

Next