Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

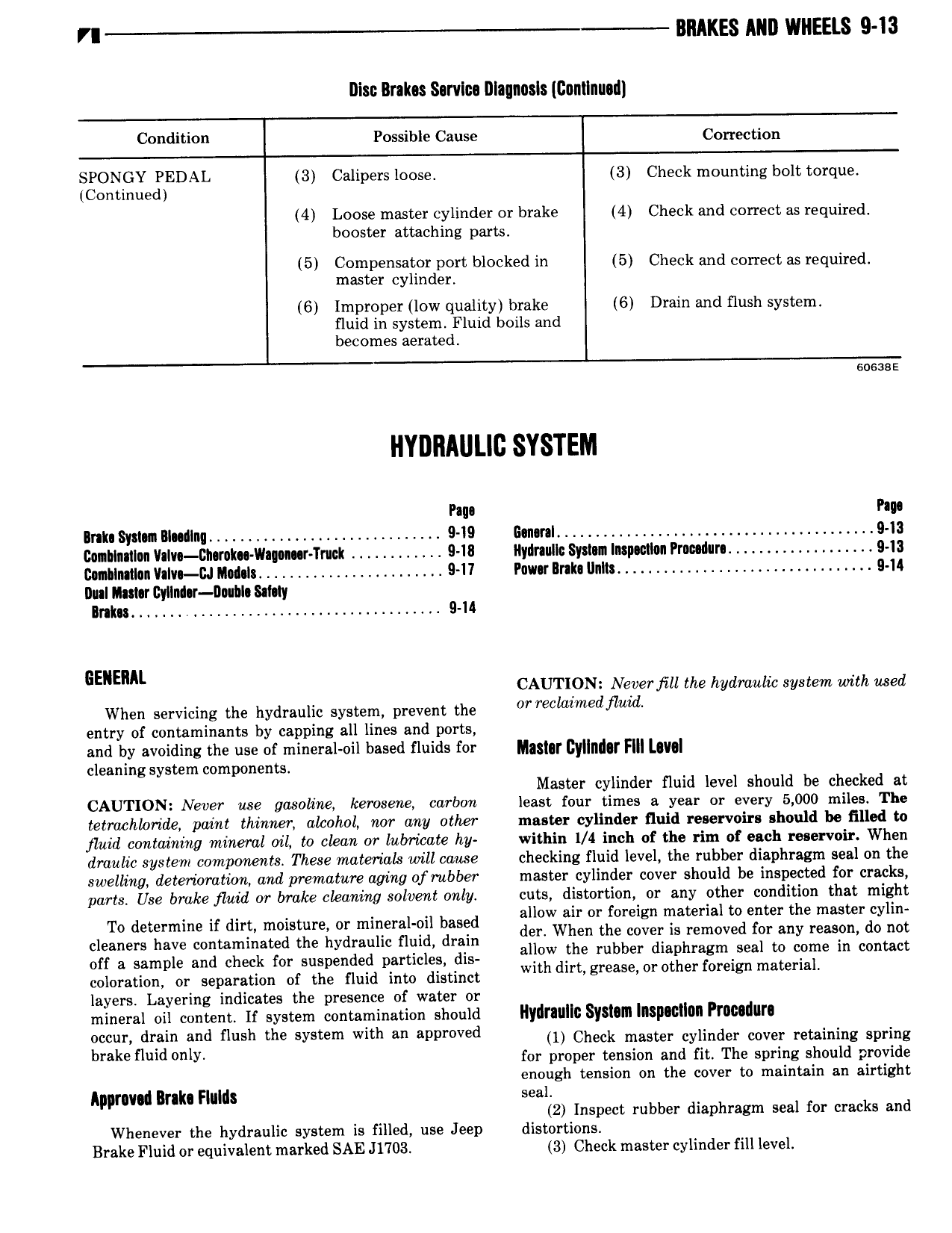

VI BRAKES Allll WHEELS 9 13 msc Bnkos Sarvlca Illaqnusls Continued Condition Possible Cause Correction SPONGY PEDAL 3 Calipers loose 3 Check mounting bolt torque Continued 4 Loose master cylinder or brake 4 Check and correct as required booster attaching parts 5 Compensator port blocked in 5 Check and correct as required master cylinder 6 Improper low quality brake 6 Drain and flush system fluid in system Fluid boils and becomes aerated soma Pm Pap Inn Symn B1 lInq 9 19 n nI 9 13 Conblnllim v lU lillU lkH wI 1l IH Ilfllllk 9 18 Ilytraullc Sym ln p 1 11u i Pr c lur 9 13 Cnnhlnailan V Iv 13 l II d 1a 9 11 Puvnr Ir k llnlts 9 14 llsal I 1 r 1 y1InI r Dsublu Satnly Ilnku 9 14 GENERAL CAUTION Never fill the hydrauhb system with used When servicing the hydraulic system prevent the M reCL medfl l entry of contaminants by capping all lines and ports and by avoiding the use of mineral oil based fluids for Mggigr Byllndgr F g cleaning system components Master cylinder fluid level should be checked at CAUTION Never use gasoline kerosene carbon least four times a year or every 5 000 miles The tetrachloride paint thinner alcohol nor any other master cylinder flnid reservoirs should be filled to fluid containing mineral oil to clean or lubricate hy within 1 4 inch of the rim of each reservoir When draulic system components These materials will cause checking fluid level the rubber diaphragm seal on the swelling deterioration and premature aging of rubber master cylinder cover should be inspected for cracks parts Use brake fluid or brake cleaning solvent only cuts distortion or any other condition that might To determine if dirt moisture or minemlwn based allow air or foreign material to enter the master cylin cleaners have contaminated the hydraulic fluid drain ggzwwmn b V sl m Bd Yr ny s dg off a sample and check for suspended particles dis with dirt mage T glerigreisnm tes C0 coloration or separation of the fluid into distinct g 0 0 0 g a layers Layering indicates the presence of water or mineral oil content If system contamination should llyllflllllll Sl Il1lI p0I il0Ill 1 1l1 ll Ifl occur drain and flush the system with an approved 1 Check master cylinder cover retaining spring brake fluid lY for proper tension and fit The spring should provide enough tension on the cover to maintain an airtight Approval Bran Fluldi seal 2 Inspect rubber diaphragm seal for cracks and Whenever the hydraulic system is filled use Jeep distortions Brake Fluid or equivalent marked SAE 11703 3 Check master cylinder fill level

Next

Next