Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

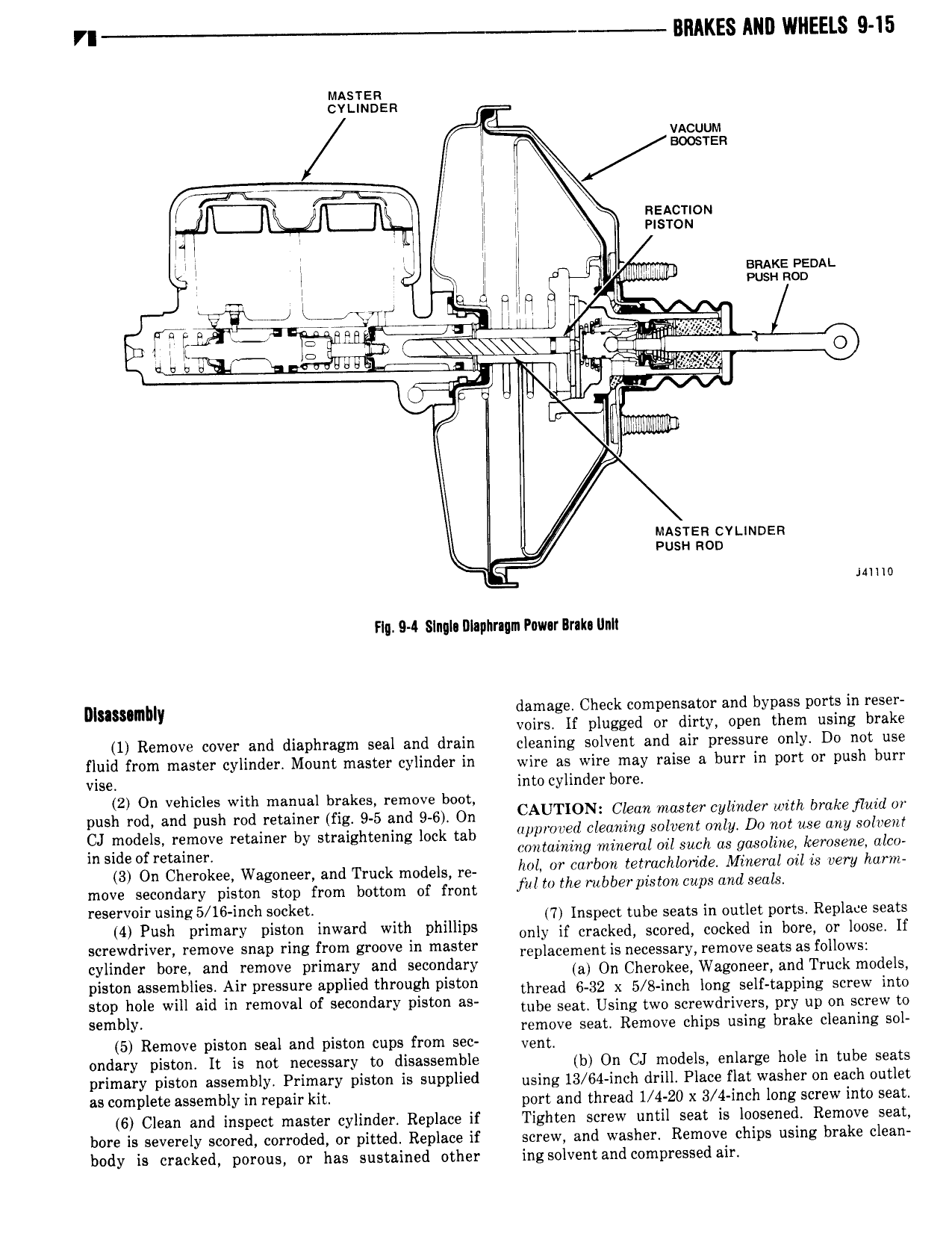

r BRAKES AND WHEELS 9 15 MAsrzs cvtiuozn l vacuum l soosrsn li l L l l l i l ngigrion e i S er N l l l l I i 2 i l l F wlilltlt L 5 E g 1 gl 3 lll W A I VT iii Fa I l i Zi d l r l 2 w l sm e 11 llF Wl 5 a e Jli I I si uv P i lllmilllllllllllll i Y l MASTER cvuunen pusu non main Flq 9 4 Slngln Dlaplnrnqm Puvnr Iirak Unit n ug mb y damage Check compensator and bypass ports in reser voirs if plugged or dirty open them using brake 1 Remove cover and diaphragm seal and drain cleaning solvent and air pressure only Do not use fluid from master cylinder Mount master cylinder in wire as wire may raise a burr in port or push burr vise into cylinder bore 2 On vehicles with manual brakes remove boot push rod and push rod retainer fig 9 5 and 9 6 On CAUTION Ciem muster vvlmgr with brake flu 0 CJ medelev remove retainer by Straightening lock tab upproiwed cleaning solvent only 0 not use any so ten in side of remmen cmztalnzng nuneral ozl such as gosolzne kerosene alco 3 On Cherokee Wageneem end Truck models re hol or carbon tetrachloride Mineral oil is very harm move secondary piston stop from bottom of front f It th e bbe ip t pS a dSe l reservoir usmg 5 16 m h S k 7 Ins ect tube seats in outlet ports Replace seats P ii a ii mr D 4 Aus primary P S mwar wlt D I ms only if cracked scored cocked in bore or loose If screwdrlven r m V Snap rmg mm gr V m master replacement is necessary remove seats as follows cylinder bore and remove primary and secondary 8 On Cherokee Wageneen and Truck models piston assemblies l 1r pressure applied through piston thread 632 X 5 Bench Ong Selhapping screw imo stop hole will aid in removal of secondary piston RS tube sean Using two Screwdrivers pry up on screw to mblv remove seat Remove chips using brake cleaning sol 5 Remove piston seal and piston cups from sec vent ondary piston It is not necessary to disassemble b On CJ models enlarge hole in tube seats primary piston assembly Primary piston is supplied using 13 64 inch drill Place flat washer on each outlet as 0mPl assembly in Fellalf kit port and thread 1 4 20 x 3 4 inch long screw into seat 6 Clean and inspect master cylinder Replace if Tighten screw until seat is loosened Remove seat bore is severely scored corroded or pitted Replace if screw and washer Remove chips using brake clean body is cracked porous or has sustained other ingsolventandcompressedair

Next

Next