Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

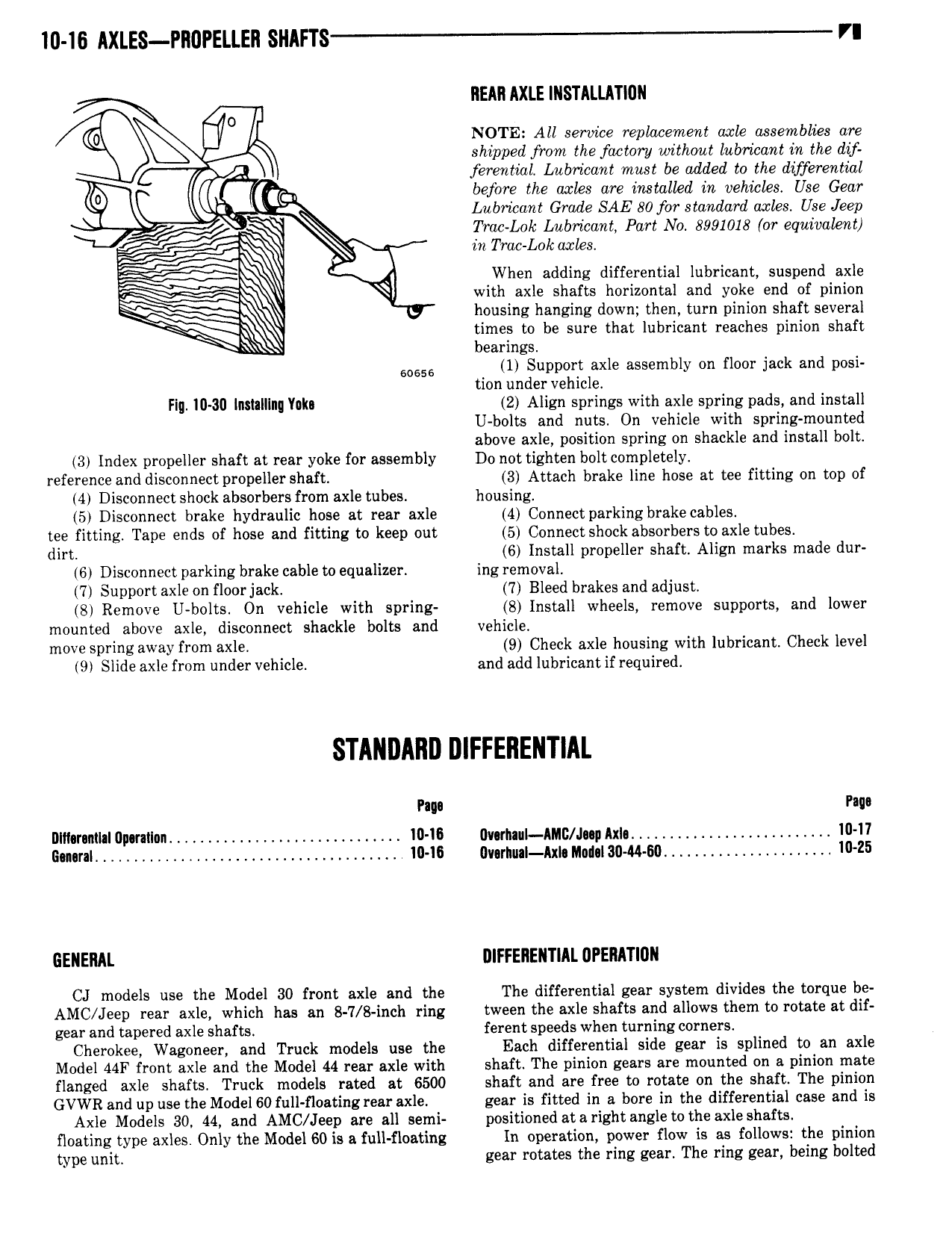

991018

I0 I6 AXLES PRDPELLER SNAFTS VI REAR AXLE INSTALLATIDN X NOTE All service replacement axle assemblies are shipped from the factory without lubricant in the dif ferential Lubricant must be added to the differential Q before the axles are installed in vehicles Use Gear l Lubricant Grade SAE 80 for standard axles Use Jeep x Trac Lok Lubricant Part No 8 991018 or equivalent in Trac Lok axles When adding differential lubricant suspend axle al with axle shafts horizontal and yoke end of pinion x housing hanging down then turn pinion shaft several times to be sure that lubricant reaches pinion shaft k bearings 60555 1 Support axle assembly on floor jack and posi tion under vehicle Fig ID 30 Inthlllnq Volt 2 Align springs with axle spring pads and install U bolts and nuts On vehicle with spring mounted above axle position spring on shackle and install bolt 3 Index propeller shaft at rear yoke for assembly Do not tighten bolt completely reference and disconnect propeller shaft 3 Attach brake line hose at tee fitting on top of 4 Disconnect shock absorbers from axle tubes housing 5 Disconnect brake hydraulic hose at rear axle 4 Connect parking brakecables tee fitting Tape ends of hose and fitting to keep out 5 Connect shock absorbers to axle tubes dirt 6 Install propeller shaft Align marks made dur 6 Disconnect parking brake cable to equalizer ing removal 7 Support axle on floorjack 7 Bleed brakes and adjust 8 Remove U bolts On vehicle with spring 8 Install wheels remove supports and lower mounted above axle disconnect shackle bolts and vehicle move spring away from axle 9 Check axle housing with lubricant Check level 9 Slide axle from under vehicle and add lubricant if required STANDARD DIFFERENTIAL Faqs PIM Dltlmntlal Opmtlon ID 16 0v ma l AMD Jap AxI IU 17 Iimral Il I6 0v rhu l Ark Modal 30 44 60 I0 Z5 GENERAL DIFFERENTIAL UPERATIDN CJ models use the Model 30 front axle and the The differential gear system divides the torque be AMC Jeep rear axle which has an 8 7 8 inch ring tween the axle shafts and allows them to rotate at dif gear and tapered axle shafts ferent speeds when turning corners Cherokee Wagoneer and Truck models use the Each differential side gear is splined to an axle Model 44F front axle and the Model 44 rear axle with shaft The pinion gears are mounted on s pinion mate flanged axle shafts Truck models rated at 6500 shaft and are free to rotate on the shaft The pinion GVWR and up use the Model 60 full floating rear axle gear is fitted in a bore in the differential case and is Axle Models 30 44 and AMC Jeep are all semi positioned ataright angle to the axleshafts floating type axles Only the Model 60 is a full floating In operation power flow is as follows the pinion type unit gear rotates the ring gear The ring gear being bolted

Next

Next