Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

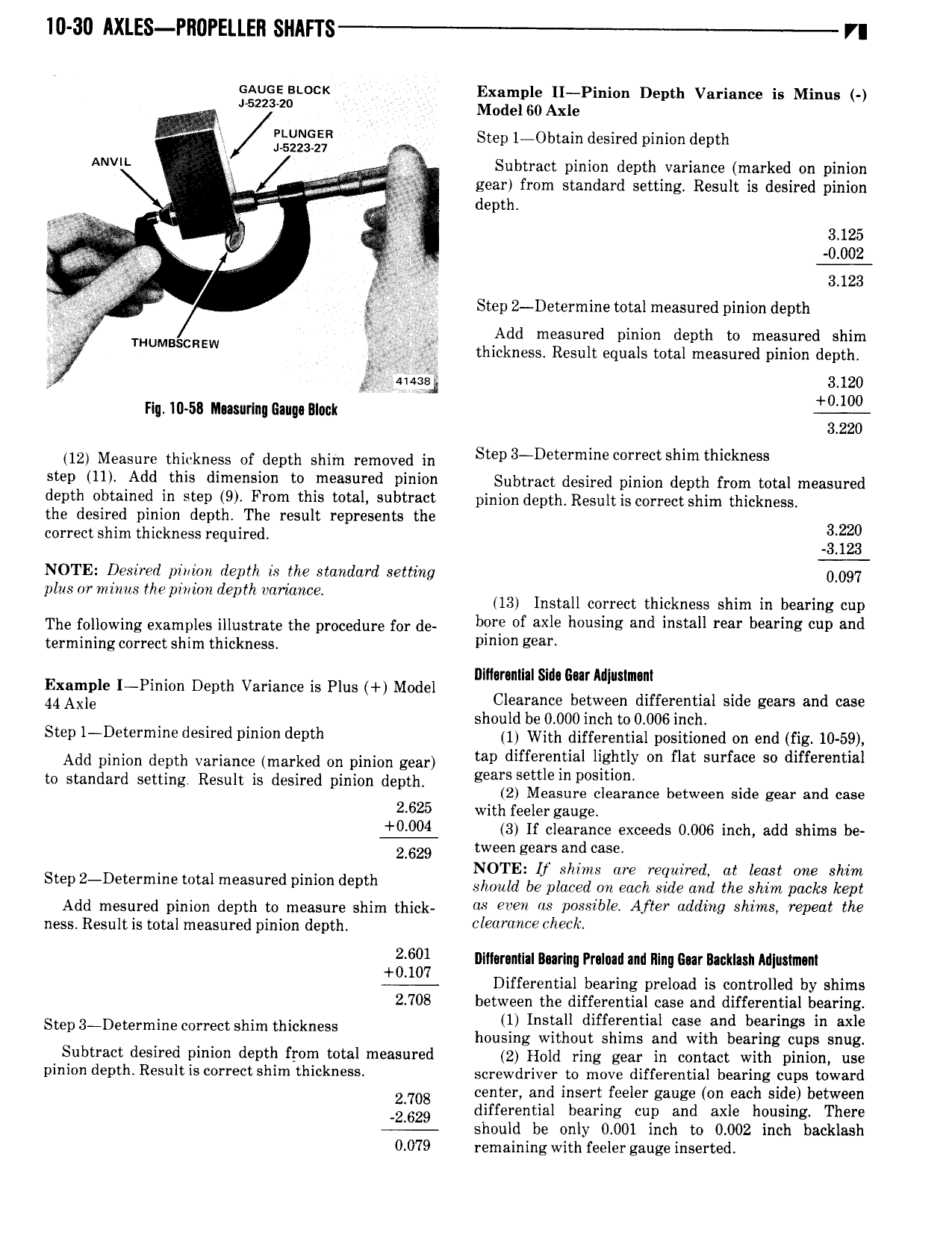

10 30 AXLES PBUPELLEH SHAFl S VI Au e stock Example II Pinion Depth Variance is Minus m Model so Axle p UNGER Step 1 Obtain desired pinion depth Jazz zv ANVIL Q Subtract pinion depth variance marked on pinion xg gear from standard setting Result is desired pinion 9 depth is zi 3 125 e eh M ii 4 L 2 i lfisiii 3 123 4 an 5 jig Step 2 Determine total measured pinion depth Iii Add measured pinion depth to measured shim THUMBSCREW gc a thickness Result equals total measured pinion depth ling 3 120 0 100 Fig 10 58 Maasurlng Ganga Blank w 22 dz ne suie tii i es of depth shim removed in Step3 Detein e m l inlhieleieee step ll Add this dim Si0 to 8S 1 d pinion Subtract desired pinion depth from total measured depth obtained in step 9 From this total subtract pinion depth Result is correct shim thickness the desired pinion depth The result represents the 3220 correct shim thickness required 3 IZ3 NOTE Desired pltiion depth is the standard setting 04097 plusoir minus lh piuiml depth Mmmm 13 Install correct thickness shim in bearing cup The following examples illustrate the procedure for de bt ef axle l Sl g and lllstall rear bearing cup and termining correct shim thickness plmm geal 4 A Dlliaranilalslda Gaarkdlusimant Example I Plnion Depth Variance is Plus Model 44 Axle Clearan between differential side gears and case ce g should be 0 000 inch to 0 006 inch tep1 Detennine desired pinion depth 11 With differential positioned on end fig 10 59 Add pinion depth variance marked on pinion gear gilgrglggfairgzagugggggy ee flat Surface so differential to standard setting Result is desired pinion depth 2 Measure clearance between side gear and case 2 625 with feeler gauge 0 004 3 lf clearance exceeds 0 006 inch add shims be 24629 tween gears and ease NOTE lf shims are required at least one shim Step 2 D t l ml e tctal measured plmon depth should be placed on each stile and the shim packs kept Add mesured pinion depth to measure shim thick 08 even me pvS ihie After dddiw shims repeat the ness Result is total measured pinion depth l h Ck 2601 Dlllaramlal Ilaarlnu Praloail and lling Eur Backlash Aitlualmanl Differential bearing preload is controlled by shims 2 708 between the differential case and differential bearing stepsepeterniineeorreetshini tintimes 0 Install d ee el me and e me housing without shims and with bearing cups snug Subtract desired pinion depth from total measured 2 Hold ring gear in contact with pinion use pinion depth Result is correct shim thickness screwdriver to move differential bearing cups toward center and insert feeler gauge on each side between 2 708 2 629 differential bearing cup and axle housing There should be only 0 001 inch to 0 002 inch backlash 0 079 remaining with feeler gauge inserted

Next

Next