Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

940657

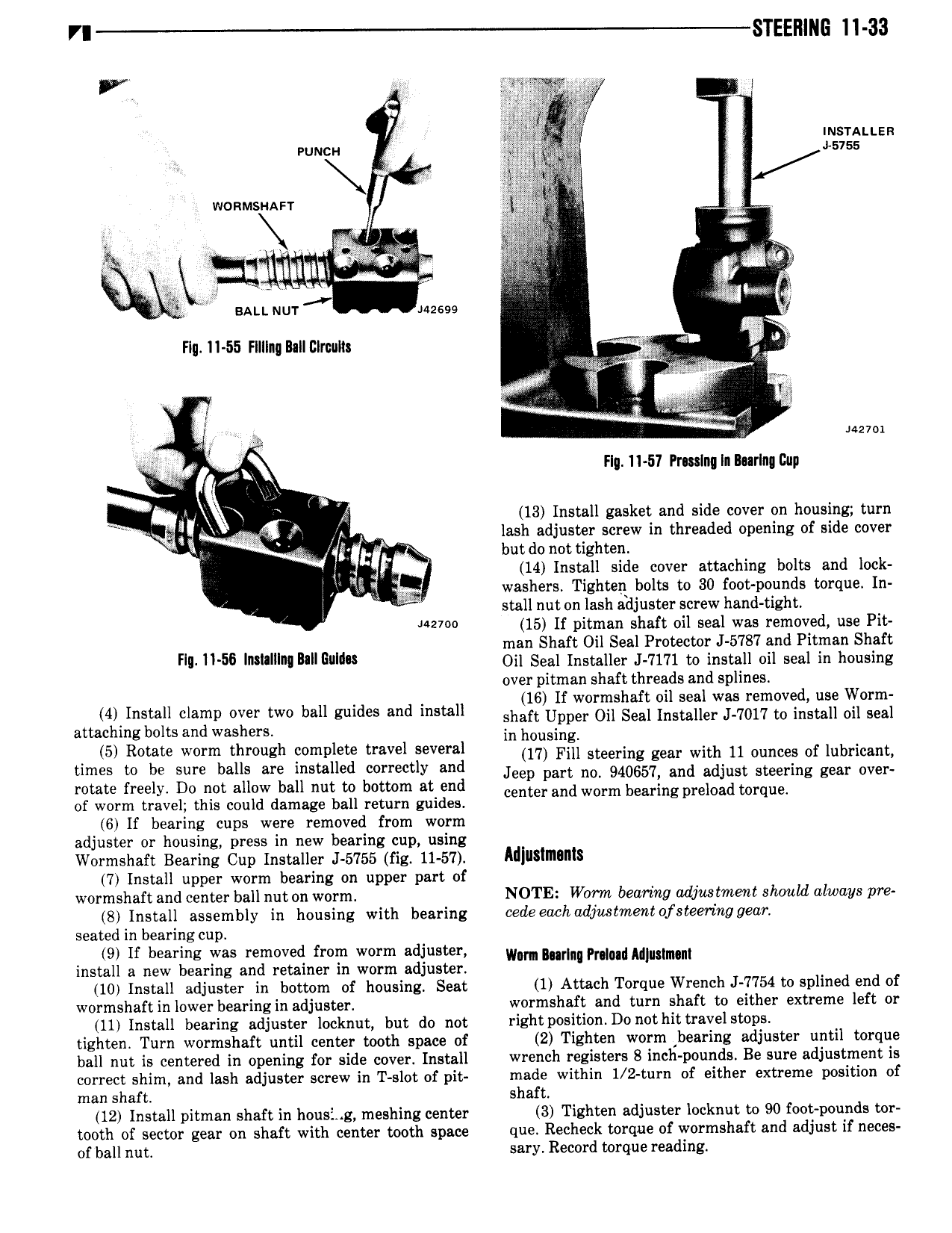

VI STEElllllG ll 33 9 I YY L L L woamsrtarr V E N i i iIR 1 gi BALL Nur mess Flu 11 55 Fllllng Balllilrcults E J i 4 f Flq 11 57 Pruslng In B arIn Buy a i 13 Install gasket and side cover on housing turn 1 sx 4 lash adjuster screw in threaded opening of side cover but do not tighten r 14 Install side cover attaching bolts and lock z washers Tighten bolts to 30 foot pounds torque In 3 stall nut on lash adjuster screw hand tight uzvoo 15 If pitman shaft oil seal was removed use Pit man Shaft Oil Seal Protector J 5787 and Pitman Shaft Fh HPS Mullin mn mu Oil Seal Installer J 7171 to install oil seal in housing over pitman shaft threads and splines 16 If wormshaft oil seal was removed use Worm 4 I 1 wmv M two bell shaft upper ou sen Installer mm to install oil seal attaching bolts and washers in housing 5 R W e m tml Semi on rm ttm gw with 11 sms of lubricant times to be sure balls are installed correctly and Jeep part no 940657 and adjust Steering gear ver rotate freely Do not allow ball nut to bottom at end T of worm travel this could damage ball return guides center and Worm beumg preload mrqua 6 lf bearing cups were removed from worm adjuster or housing press in new bearing cup using Wormshaft Bearing Cup Installer J 5755 fig 11 57 Mlllillllllls 7 Install upper worm bearing on upper part of wormshaft and center ball nut on worm NOTE Worm bearing adjustment should always pre 8 Install assembly in housing with bearing oede each adjustment ofsteering gear seated in bearing cup 9 If bearing was removed from worm adjuster wum lama Pnmd Mlmmm install a new bearing and retainer in worm adjuster 10 Install adjuster in bottom of housing Seat 1 Attach Torque Wrench J 7754 to splined end of wormshaft in lower bearing in adjuster wormshaft and turn shaft to either extreme left or 11 Install bearing adjuster Iocknut but do not right p0Biti0 D0 lwthif l VBlSi 0D5 tighten Turn wormshaft until center tooth space of 2 Tighten worm Abearing adjuster until torque ball nut is centered in opening for side cover Install wrench registers 8 inch pounds Be sure adjustment is correct shim and lash adjuster screw in T slot of pit made within 1 2 turn of either extreme position of man shaft shaft 12 Install pitman shaft in housing meshing center 3 Tighten adjuster locknut to 90 foot pounds tor tooth of sector gear on shaft with center tooth space que Recheck torque of wormshaft and adjust if neces of ball nut sary Record torque reading

Next

Next